2000W

$18,900.00

MCF Trolley Laser Cleaning Series

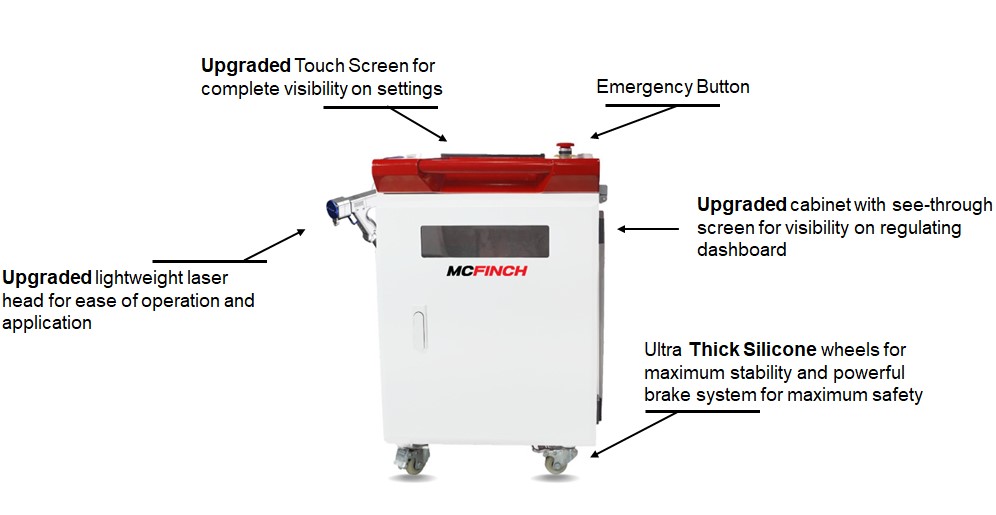

The MCF Trolley series offers the perfect mobile solution with a durable and portable carriage that integrates all components. It boasts the highest cleaning speed and power, thanks to its 2000W or 3000W power source. It is specifically designed for convenient maneuverability within factory halls or open spaces. With its versatile and lightweight laser gun, modern and portable design, powerful source, and user-friendly operation, the MCF series is the ideal machine for all your cleaning, stripping, restoration, and surface preparation requirements

A powerful, reliable, dependable laser cleaning machine that will change your game for rust removal, paint stripping, coating removal, biofilm removal, and much more!

Our MCF Trolley Series offers the highest:

- Cost-effectiveness

- Efficiency

- Precision

- Versatility

- Environment-friendly solution

- Power for the toughest jobs

How our Laser Technology works

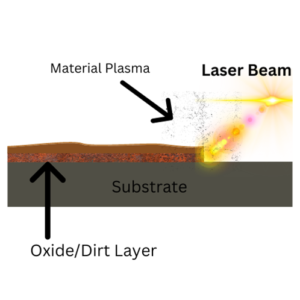

Laser technology for the purpose of removing rust, dirt, paint, and any other element on top of a substrate works through a process called ‘Ablation’.

Ablation is the process where a high-energy laser beam is directed at the surface where it rapidly causes the rust, dirt, paint, to vaporize or sublime, which means it goes from a solid state directly to a gas without passing through the liquid phase. As a result, the outer layer of the surface treated is physically removed, leaving behind a completely clean substrate.

This process is 100% clean, precise, and controllable.

Our Laser Technology offers

key advantages vs traditional methods

- No abrasive chemicals to work with Chemical use for treating and cleaning surfaces is a thing of the past. You don’t need to deal with chemicals harmful to the environment and to the human body. In addition to not having to deal with disposing of them and the risk and cost associated with doing so.

- No blasting, no mess, no downtime Surface blasting (sand, dry ice) generates a significant amount of waste material in the form of abrasive particles and removed rust/paint that will have to be cleaned up after the work is done. Your downtime is also a cost to you. Our laser technology produces minimal waste by vaporizing the targeted surface without leaving behind residue or abrasive media to clean up. No downtime!

- Precision Laser technology allows for precise control over the removal process. The laser beam can be accurately directed to target only the target areas, leaving the underlying material intact. This precision is particularly valuable when working on delicate or intricate surfaces where sandblasting may cause damage.

- Non-contact process Laser rust removal is a non-contact method, meaning there is no physical abrasion or impact on the surface. This eliminates the risk of surface deformation or damage that can occur with sandblasting, for example, which relies on the force of abrasive particles hitting the surface.

- Selective removal Laser systems can be adjusted to selectively remove rust while preserving the original material. This capability is especially useful when dealing with surfaces where complete removal of the rust is not necessary or desired.

- No secondary waste Sandblasting generates significant amounts of waste material in the form of abrasive particles and removed rust. Laser rust removal produces minimal waste, as the rust is vaporized and removed without leaving behind residue or abrasive media to clean up.

- Environmentally friendly Laser rust removal is a cleaner process compared to sandblasting and chemical application/dipping, which can be harmful to the environment. Laser systems typically operate with lower energy consumption and are 100% environmentally sustainable.

- Versatility Laser systems can be used on a wide range of materials, including metals, plastics, ceramics, and composites. Sandblasting, on the other hand, may be limited to certain materials and can be more challenging to apply on sensitive or fragile surfaces.

- Reduced surface preparation Laser rust removal can often be performed without extensive surface preparation. Unlike sandblasting, which requires masking or covering of adjacent areas, or chemical application which requires extensive preparation pre and post-work, laser technology can target specific spots without affecting surrounding surfaces, reducing the need for preparation time and effort.

Our state-of-the-art technology and design

makes the MCF Trolley Laser Cleaning Series

the best you can get

Modern, convenient, and portable design suited for ease of mobility and ease of operation

Ergonomic and lightweight laser head for ease of maneuverability and application

Our laser head is highly durable and reliable

Multi Setting and Multi Language Touch Screen for ease of operation

The best at your disposal for the toughest jobs,

and for the cleanest and fastest finish